Which operations of a routing or recipe in R/3 or ERP are transferred to APO PPMs?

When PPMs are created in APO from Receipes in R/3 only those phases containing non-zero machine times are brought over. Other phases having only labour (resource category 003) or machine time (resource category 001) = 0 does not come through.

What determines the validity period of a resource in liveCache?

CFC9 parameter in R/3 does not set the From/to validity date for Resources when Work Centres are CIFed from R/3 to APO. Actually that is set as per entry in table /SAPAPO/RESLCT - Length of Time Stream or Bucket Vector in liveCache.

What needs to be done to debug CIF related enhancements?

In order to debug CIF related user exits or other CIF queues, set the R/3 RFC user (e.g. STGUSER) to Dialog user and then set queues to Debugging On/Record T/QRFCs in the transaction CFC2 in R/3. This is for queues coming inbound to APO. For queues coming inbound to R/3 set the APO RFC user id (e.g. APSUSER)

How can transaction data be reconciled with APO from R/3 or ERP side?

Program RCIFORDT can be used to reconcile transaction data form R/3 side. Refer 733110 - as a long term solution implement this BADI on APO side

OSS Notes 627630, 804034 on R/3 side and with the BADI OSS note 800286 to be applied

Which table stores Change Pointers in ERP or R/3?

The table BDCPV is to store Change Pointers in both APO and R/3.

Refer OSS Note 329110.

Which report can be used to clear Change Pointers in ERP or R/3?

Program RBDCPCLR can be used to clear change pointers from the Change Pointer table. The message type CIFSRC is for changes to Source of Supply (i.e. Purchasing Inforecords). The CIF Change Transfer program (CFP1) can fail due to a large number of records in the Change Pointer table. Other message types are CIFMAT for material, CIFVEN for Vendor Master, CIFCUS for Customer master.

What is Customer Consignment Stock and how is it transferred to APO?

Consignment stock at Customer is stock at customer premises but owned by the supplier. Prerequisite to have Consignment Stock at Customer is Customer as a Location and Product Master at that Customer Location. To transfer Customer Consignment Stock from ERP to APO both "Customer" and "Special Stock at Customer" should be part of an Integration Model during Initial Transfer. For Consignment Stock Batches "Storage Location Stock" object must be included in the Integration Model.

Reference: Note 409298

What is Vendor Consignment Stock and how is it transferred to APO?

Vendor Consignment stock is stock at the plant location and treated as normal storage location stock but owned by vendor. Vendor Consignment Stock is transferred from ERP to APO as part of "Storage Location Stock" Integration Model. However the Vendor must be part of an active

Integration Model.

How is Stock information stored in APO?

Stock in SCM APO system (upto 4.1) consists of Stock Anchor stored in Database and Stock Item stored in liveCache. The liveCache Consistency Check (transaction /SAPAPO/OM17) carries out the consistency check between the APO Database and liveCache. It should be executed periodically to delete obsolete stock anchors from the database.

Reference: Note 492591

As of SCM 5.0 Stock information is stored in liveCache table /SAPAPO/STOCKANC.

Reference: Note 837744

What are the userexits for Integration of Stocks?

On R/3 side the userexit is enhancement CIFSTK01 while on APO side it is enhancement APOCF011. The source code in the userexit should be copied to the CIF Compare/Reconcile Report (Delta Report) BAdI (method RELEVANT_FOR_COMPARE_R3_STOCK of BAdI definition /SAPAPO/CIF_DELTA3) for correctness of the report.

Reference: Note 492591

How is Inspection Lots handled in APO?

From SCM 4.0 Inspection Lots are separate objects in APO retaining the end dates. Hence Inspection Lots quantities does not shows up as Stock in Quality Inspection.

How is Cross-company Stock In Transit handled in APO?

Cross-company Stock In Transit is determined dynamically in R/3 and hence not transferred to APO. In APO Stock In Transit at the receiving plant can be handled by transferring Inbound Shipping Notification or Goods Confirmations from R/3.

What is the Data Load for Transaction Data that the CIF can typically handle in a day?

"It Depends" (need better answer here)

Showing posts with label SAP APO CIF. Show all posts

Showing posts with label SAP APO CIF. Show all posts

Monday, November 29, 2010

Friday, November 26, 2010

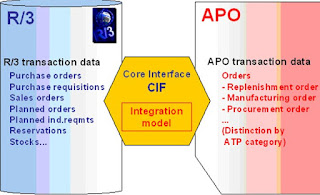

R/3 - APO Integration and Overview of APO CIF

This article will explains you the overview of Core interface and the integration of ECC to APO.

Interfaces are responsible for the integration of ECC with SAP BW or SAP APO or SAP SRM or SAP SEM or SAP CRM are made available using corresponding plug-in. The interface between ECC and SAP APO is called an Core Interface (CIF).

SAP SCM(APO) is used in connection with other SAP system or non SAP systems. There are two different ways we can able to approach.

1. Linkage with non ECC systems, this we can able to approach with BAPI’s

2. Linkage with one or more ECC systems, this we can able to approach with CIF.

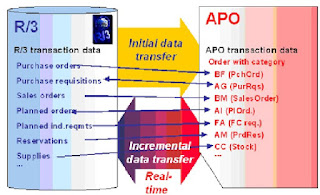

Transactional Data Interface:

The results of planning in APO are returned to ECC via CIF. This integration of transaction data takes place in real time.

Transactional Data Objects:

This is usually followed automatically by the incremental data transfer between R/3 and APO for transaction data objects that are members of an active integration model. This means that new transaction data or changes to existing transaction data are transferred automatically.

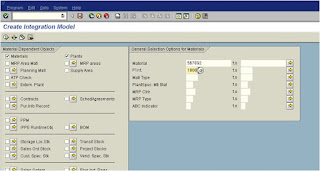

Integration Model:

The selection of master data or transaction data that the system transfers into APO is determined in an integration model that you define in the R/3.In the integration model, you select the dataset (master or transaction data) that you want to transfer. You specify the following in the integration model:

- The APO target system for the data transfer.

- The data objects you want to transfer.

The target system that you specify in the integration model determines the APO System that the master data is transferred into. The target system is a logical (APO) system that must have a RFC connection.

To create an integration model in R/3 the available transaction code is CFM1.

The master data that the system will transfer for the first time (initial transfer), from the R/3 System into the APO System, is defined in an integration model. The R/3 System generates this integration model.An integration model is uniquely defined by its name and application. Integration model has to be created in R/3.

Path: SAP MENU -> Logistics -> Central Functions -> Supply Chain Planning Interface -> Core Interface Advanced Planner and Optimizer -> Integration Model -> Generate -> Create.

Provide a name for the integration model, Logical system name (APO logical system name), and MD as APO Application.

MD indicates that we are transferring Master Data.

Select Materials, Plant, PPM, BOM and Work Center check boxes.

You can also create Integration model for each category that you want to transfer.

Eg: you can create one integration model for materials, another for plants and so on.

Now you have to specify the materials that you transfer by providing the Material names/no in the corresponding fields.

For Eg: In the above screen shot, 567892 is mentioned for Material and 1000 for plant.

It indicates that only 567892 in plant 1000 will be transferred to APO.

In similar fashion, give values for PPM, BOM, Work Centers.

To provide the values, click on the button adjacent to the Check box.

After you have specified all the values, click on Execute button.

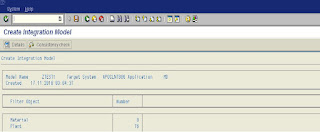

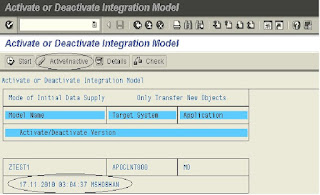

After you click save, you will get a message “ Integration model ZTEST1 generated for target system APOCLNT800 and application MD”

Once we create an integration model we need to activate the generated model for initial data transfer.

Select the Integration model (Highlighted in Blue) and click on Activate Button. You can as well double click on the line to activate it. If you generate the same integration model multiple time, then you will see few more lines with different time and date. Select the latest one and Activate it. After the Integration model is Active, click on Start (Execute) button to start transferring the objects into APO. After the process is complete, you can login to APO and look for the transferred objects. As long as the Integration model is Active, Changes made to the objects in Integration model will automatically be reflected in APO. If you want to the changes to be reflected in APO, then deactivate the Integration mode by clicking on Inactive button or by double clicking on the line.

CIF Interface R/3 – APO Mapping structures

CIF Interface R/3 – APO: Purchase Order:

Object : PO Documents

Enhancement : APOCF006

Exit Function Module : EXIT_/SAPAPO/SAPLCIF_PU_001

Description : I/B Processing:PO Documents

Object : PO Documents

Enhancement : APOCF024

Exit Function Module : EXIT_/SAPAPO/SAPLDM_PURCHA_001

Description : Record customer-specific order or BANF fields

R/3 - ECC Tables Involved:

Table :EKKO and Table Description : Purchasing document header

Table :EKPO and Table Description : Purchasing document item

Table :EKKN and Table Description : Account assignment in purchasing document

Table :EKET and Table Description : Scheduling agreement delivery schedule lines

Table :EKES and Table Description : Order confirmations

APO Table Involved:

Table Table Description

/SAPAPO/IF_ORDER_HEAD_TAB , Order header data

/SAPAPO/IF_ORDER_OUTPUT_TAB , Output node for order or operation

/SAPAPO/IF_ORDER_INPUT_TAB , Planned/production order input nodes

/SAPAPO/IF_ORDER_OPR_TAB, Operations of an order

/SAPAPO/IF_ORDER_RELATION_TAB , Operation relationships

/SAPAPO/IF_ORDER_CAPREQ_TAB, Capacity requirements for an order or operation

Subscribe to:

Posts (Atom)